Builtec uPVC Pressure pipes are produced according to BS 3505:1968 incorporating amendments issued in August 1972 (AMD 1014) and July 1975 (AMD 1773) and PS 3051:1991 and under license from Pakistan Standards and Quality Control Authority (PSQCA) Ministry of Science and Technology Govt. of Pakistan.

Builtec uPVC Pressure pipes are produced according to BS 3505:1968 incorporating amendments issued in August 1972 (AMD 1014) and July 1975 (AMD 1773) and PS 3051:1991 and under license from Pakistan Standards and Quality Control Authority (PSQCA) Ministry of Science and Technology Govt. of Pakistan. These pipes are also produced with other international Standards. pipesBuiltec uPVC Pipes are also approved by secretary HUD & PHE Department Govt. of Punjab and PHE Department Govt. of Balochistan for use in their water supply projects.

Nominal Size Wall Thickness Pressure Class-B 200 FT Head (6 Bar) Pressure Class-C 300 FT Head (9 Bar) Pressure Class-D 400 FT Head (12 Bar) Pressure Class-E 500 FT Head (15 Bar) Inches Outer Diameter MM Individual Value MM Individual Value MM Individual Value MM Individual Value MM Min Max Min Max Min Max Min Max Min Max 1/2″ 21.2 21.5 . . . . . . 1.7 2.1 3/4″ 26.6 26.9 . . . . . . 1.9 2.5 1″ 33.4 33.7 . . . . . . 2.2 2.7 1-1/4″ 42.1 42.4 . . . . 2.2 2.7 2.7 3.2 1-1/2″ 48.1 48.4 . . . . 2.5 3.0 3.1 3.7 2″ 60.2 60.5 . . 2.5 3.0 3.1 3.7 3.9 4.5 2 1/2″ 75.0 75.3 . . 3.0 3.5 3.9 4.5 4.8 5.5 3″ 88.7 89.1 2.9 3.4 3.5 4.1 4.6 5.3 5.7 6.6 4″ 114.1 114.5 3.4 4.0 4.5 5.2 6.0 6.9 7.3 8.4 5″ 140.0 140.4 3.8 4.4 5.5 6.4 7.3 8.4 9.0 10.4 6″ 168.0 168.5 4.5 5.2 6.6 7.6 8.8 10.2 10.8 12.5 7″ 193.5 194.0 5.2 6.0 7.7 8.9 10.1 11.7 12.4 14.3 8″ 218.8 219.4 5.3 6.1 7.8 9.0 10.3 11.9 12.6 14.5 10″ 272.6 273.4 6.6 7.6 9.7 11.2 12.8 14.8 15.7 18.1 12″ 323.4 324.3 7.8 9.0 11.5 13.3 15.2 17.5 18.7 21.6 14″ 355.0 356.0 8.5 9.8 12.6 14.5 16.7 19.2 20.5 23.6Builtec High Pressure Pipes

Applications of Builtec uPVC Pressure Pipes

Dimensions and Maximum Working Pressure of Builtec Pipes as per BSS 3505:1968 and PS 3051 for uPVC Pipe

UPVC Soil, Waste, Vent Systems

See Product

PPRC Hot & Cold Water Supply Systems

See Product

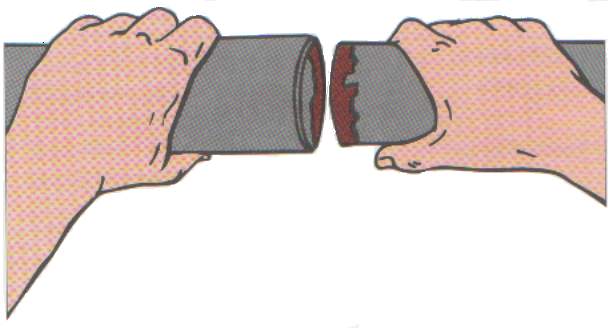

UPVC Pressure Piping Systems

See Product